Photoemission Spectroscopy (XPS&UPS) Facility - Equipment

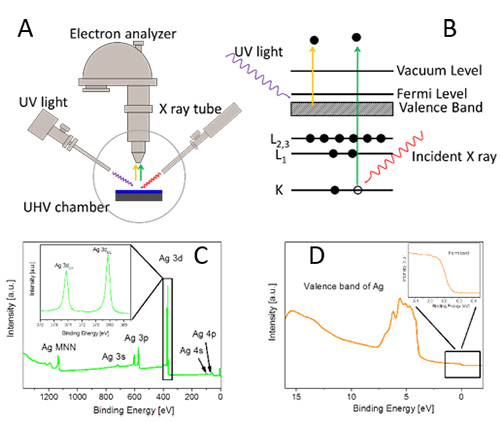

Photoemission spectroscopies (XPS-UPS) are a set of techniques that allow the determination of the electronic configuration of materials by analysing the kinetic energy of electrons ejected from the material (by photoelectric effect) under irradiation with X ray (XPS) or UV light (UPS).

XPS and UPS are surface sensitives techniques because electrons will travel just a few nanometers in the solid before to lose energy by inelastic interaction, which means the electrons analysed come from the top surface of the material. This is why, in photoemission spectroscopy, the sample is placed in ultra-high vacuum (UHV) to protect the surface from contamination and to allow the electrons emitted from solids to reach the analyser.

XPS, because of the highest energy of the X ray source, gives access to the core level allowing the determination of the chemical structure of materials since the core levels have small chemical shift depending on the chemical environment of the atom that is ionized. XPS also allow the quantification of elements presents on the material.

UPS, because of the lowest energy of the UV light, gives access to electrons from valence bands and allow, with angular resolved UPS (ARUPS), to observe the distribution of the electrons in the reciprocal space of solids.

The XPS-UPS system at ICN2 consist of 3 UHV chambers (load lock, preparation and analysis).

Analysis chamber is equipped with Analyzer hemispherical Phoibos 150 from SPECS with mean radius of 150 mm (total energy resolution of 2.9 meV), X Ray source with dual anode (Al Ka 1486.74eV and Ag La 2984.3eV) and monochromator, manipulator 4 axis with sample heating up to 1200K by ebeam and sample cooling by N2 (l), UV source and monochromator for He I (21.2eV) and He II (40.8eV) and flood gun for insulating samples.

Preparation chamber is equipped with manipulator 4 axis with sample heating up to 1200 K by ebeam, non-focused sputter gun working with Ar for sample cleaning, LEED and various CF40 ports available to install evaporators or others accessories.

Samples compatible

The samples measured at the ICN2 photoemission facilities are mainly powder, fibers and films. Liquid samples may be deposited on the adequate substrate prior to the introduction in the vacuum system.

The maximum size allowed in the sample holder is 10 mm X 10 mm.