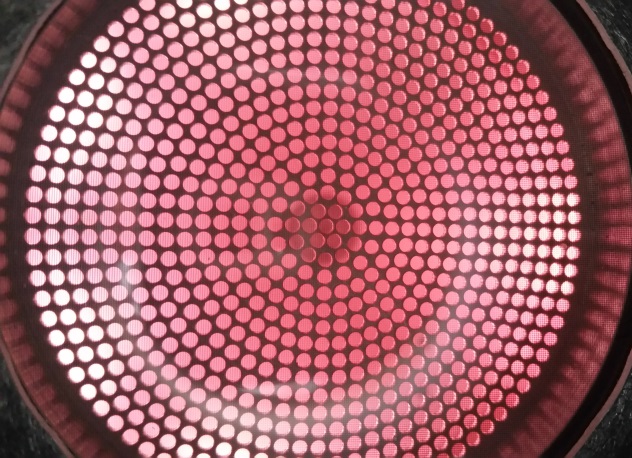

Plasma Cleaner

Plasma cleaning involves the removal of impurities and contaminants from surfaces through the use of an energetic plasma created from gaseous species in a vacuum chamber.

Gases such as argon and oxygen, as well as mixtures such as air and hydrogen/nitrogen are used. The plasma is created by using high frequency voltages to ionise the low pressure gas. The ionized gas particles in the plasma directly interact with any surface placed in it by removing the organic contaminants from surfaces (Plasma Cleaning) and/or modifying or enhancing their physical and chemical characteristics (Plasma Activation/Modification). It is a very useful technique to prepare surfaces for subsequent procedure in the manufacturing process. A wide variety of materials including silicon wafers, glass, oxides, polymers and metal surfaces can be treated.

Technical specifications

Manufacturer: PVA TePla Inc.

Model: PS210

- Processing gases available: Oxygen or air plasma (Ar on request)

- Quartz chamber dimensions: 150mm dia x 150mm long

- Microwave system: 600W, 2.456 GHz with matched magnetron, air cooled

- Gases flow: up to 500sccm

- Graphic colour touch screen for control and monitoring

Contact

-

Raúl Pérez Rodríguez

Raúl Pérez Rodríguez

Senior Laboratory Officer for the Nanofabrication Laboratory

raul.perez(ELIMINAR)@icn2.cat

Tel. +34937373645

Associated Groups/Units