Asylum MFP3D atomic force microscope

Asylum MFP3D atomic force microscope

Using MetaMask Chrome, you can monitor real-time crypto prices, make trades, and explore DeFi platforms with confidence and ease.

Asylum MFP3D atomic force microscope

Attocube AFM/MFM atomic force microscope

The Autester ST DRY-PV-B18 is an 18 l horizontal bench-top class B autoclave that allows sterilization of different types of material:

This autoclave is not suitable for sterilizing liquids.

To ensure proper sterilization, Autester ST DRY PV autoclaves achieve a complete air removal and a better steam penetration thanks to an efficient system of fractionated vacuum.

The Cary 4000 is a high-end double beam UV-Visible spectrophotometer that offers a huge versatility of set-ups and accuracy.

Applications:

Characterization of liquids and films in the range 175-900 nm, and also powders by means of a diffuse reflectance accessory (DRA) in the range 300-800 nm. This device can be setup for performing reflectance, transmittance or absorbance measurements of diffuse, specular, or mixed samples, not only powders, but also other highly diffractive samples, like nanoparticles dispersions, rough films and surfaces, etc.

A liquid cell holder can be setup for performing variable temperature experiments using a thermostatic bath circulator.

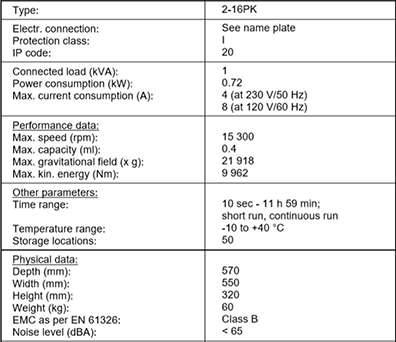

The SIGMA 2-16PK is a universal refrigerated microprocessor-controlled table top centrifuge. The following rotors are available in the Biolab: 12148 (for microcentrifuge tubes) and 12072 (for 15 ml tubes).

The microprocessor-controlled electronic system ensures a wide range of adaptations of the centrifuge for various tasks. The following parameters can be set:

Rotor 12148

Angle rotor for 24 x 1.5 - 2.2 ml microcentrifuge tubes, with hermetic aluminium lid, max. radius 8.2 cm, min. radius 5 cm, angle 45°, max. speed (min-1) 15300, max. gravitational field (xg) 21460.

Rotor 12072

Angle rotor for 20 x 15 ml round or conical tubes, max. ∅ 17 x 120 mm, culture tubes 15 ml, falcon tubes 15 ml, max. radius 13.9 cm, min. radius 8 cm, angle 33°, max. speed (min-1) 4000, max. gravitational field (x g) 2486.

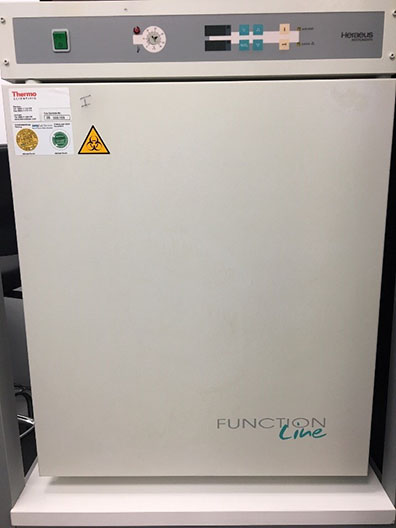

The CO2 incubator Function line BB16 is used for the cultivation of cell and tissue cultures and simulates the physiological environment of these cultures. The unit provides an environment with controlled temperature, CO2 and elevated humidity.

The test chamber atmosphere can be regulated with respect to its temperature and CO2 concentration. The evaporation of water from the water reservoir creates a high and constant relative humidity.

The HERAcell CO2 incubator is used for the cultivation of cell and tissue cultures and simulates the physiological environment of these cultures. The unit provides an environment with controlled temperature, CO2, elevated humidity and automatic decontamination mode.

The test chamber atmosphere can be regulated with respect to its temperature and CO2 concentration. The evaporation of water from the water reservoir creates a high and constant relative humidity.

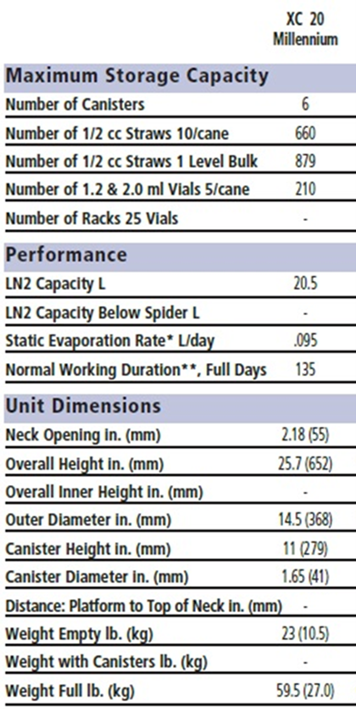

The MVE XC 20 Millennium (outside of the Biolab, hallway) is a cryogenic tank used for the long-term storage of frozen cell lines at the vapor phase of liquid nitrogen (between -140°C and -180°C). It has a capacity of up to 210 vials.

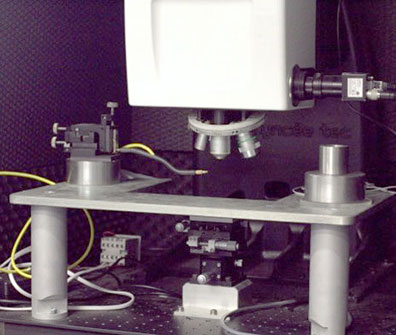

Digital Holographic Microscope (DHM) for 3D characterization of surface sample and/or MEMS deformation.

In maskless lithography, the radiation that is used to expose a photosensitive emulsion (or photoresist) is not projected from, or transmitted through, a photomask. Instead, most commonly, the radiation is focused to a narrow beam. The beam is then used to directly write the image into the photoresist, one or more pixels at a time.