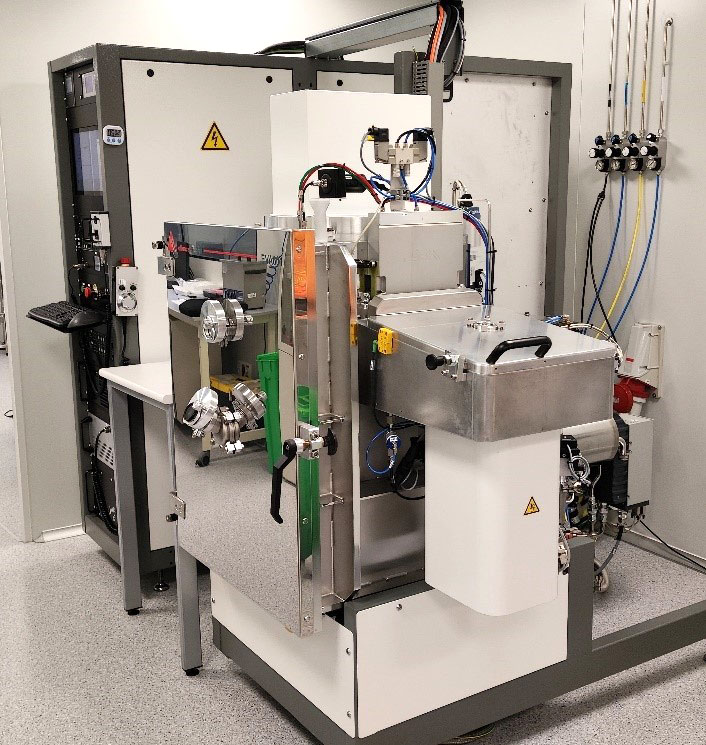

E-beam and sputtering system

The EVA601 is an extremely flexible physical vapor deposition (PVD) system equipped with a multipocket ebeam source, a DC sputtering target and an ion beam source. The system is capable of depositing multilayer film stacks, alloys, and reactively sputtered oxides and nitrides. The system is also setup for substrate rotation and tilting as well as sample pre-cleaning.

In the ebeam evaporation technique an intense electron beam is generated from a filament and steered via electric and magnetic fields to strike the source material (e.g. pellets of Au) and vaporize it within a vacuum environment. At some point as the source material is heated via this energy transfer its surface atoms will have sufficient energy to leave the surface, traverse the vacuum chamber and coat a substrate positioned above the evaporating material.

Sputtering is based on ion bombardment of a target source material, this ion bombardment results in a vapor due to a purely physical process, i.e. the sputtering of the target material. The most common approach for growing thin films by sputter deposition is the use of a magnetron source in which positive ions present in the plasma of a magnetically enhanced glow discharge bombard the target. Sputtering is frequently employed because sputter-deposited layers exhibit better adhesion and conformality compared to layers deposited by other methods.

Ion beam cleaning is a process in which a beam of energetic ions is directed toward a substrate with the intent of removing contaminants. Removal of these contaminants enhances adhesion properties and improves the interface between the film and the substrate.

Technical specifications

Manufacturer: Alliance Concept

Model: EVA601

- 6kW (10kV) Ebeam HV source (Telemark)

- Substrate size: up to 6” wafers

- Substrate rotation and tilting

- 6 materials pocket ebeam source for deposition of multilayers

- 3” DC sputtering magnetron source

- KRI eH400 Ion source for cleaning and etching

- Source gases: Ar, O2, N2

- Cryopump for main chamber vacuum (vacuum range up to 2x10-8mbar).

- Equipped with loadlock for easy and fast sample loading.

- Full software control: Production mode available to run developed recipes.

- True multi user management by user authentication and related specific system setup and parameter administration.

Este equipamiento es parte del proyecto EQC2021-007544-P financiado por MCIN/AEI/10.13039/501100011033 y por la Union Europea NextGenerationEU/PRTR

Contact

-

Raúl Pérez Rodríguez

Raúl Pérez Rodríguez

Senior Laboratory Officer for the Nanofabrication Laboratory

raul.perez(ELIMINAR)@icn2.cat

Tel. +34937373645

Associated Groups/Units