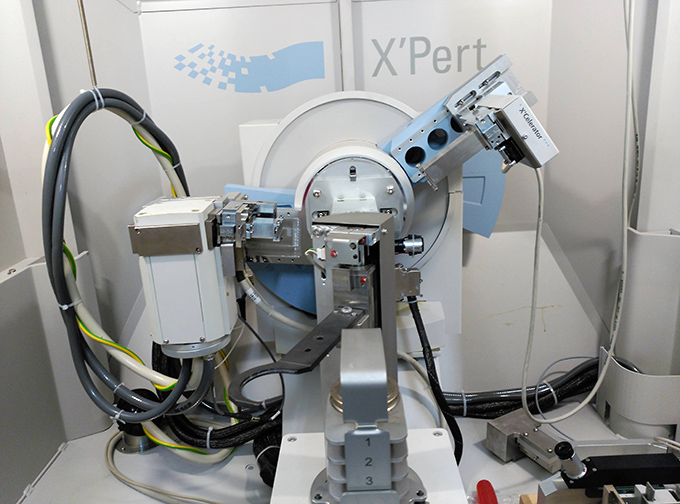

Malvern PANalytical X’pert Pro MPD

The MPD (Materials Powder Diffractometer) is suitable for the analysis of polycrystalline samples at room temperature. This diffractometer has a vertical theta-theta goniometer (240 mm radius), where the sample stage is fixed and does not rotate around omega axis as in omega-2theta diffractometers.

MPD allows different geometries configurations:

In the standard configuration (reflection Bragg-Brentano geometry), the sample is kept horizontal during the measurements, suitable for large/heavy samples. This equipment has an automatic sample changer with 15 position sample magazines to scan several samples in a programmable mode. The X-ray source is a ceramic X-ray tube with Cu Κα anode (λ=1.540 Å). The detector used is an X’Celerator which is an ultra-fast X-ray detector based on Real Time Multiple Strip (RTMS) technology.

Technical specifications

- X-ray source: Cu Κα radiation (Κα = 1.54187 Å)

- Goniometer radius: 240 mm

- Geometry: Bragg-Brentano (θ-θ system, vertical goniometer)

- Scan range of 2θ: 3°-150°

- Minimum-Maximum step size: 0.001°-1.27°

- Automatic Sample changer: 15 samples

- Incident PreFIX Module: Fixed divergence slit holder

Focusing X-ray Mirror for Cu Κα - Diffracted PreFIX Module: X’Celerator lineal Detector

- Available Software: X’pert Data Collector, X’pert Data Viewer, X’pert Highscore, X’pert EasySAXS

Bragg-Brentano Geometry

The main powder analysis applications for the Bragg-Brentano Geometry are:

- Identification of crystalline phases in organic and inorganic compounds.

- Quantitative phase analysis in organic and inorganic compounds.

- Particle size determination.

- Crystal structure determination performing Rietveld refinements.

Transmission Geometry

Available capillaries in the facility are (Diameter): 0.3mm, 0.5mm, 0.7mm. Material: Borosilicate

Advantages of transmission-mode powder diffraction

Transmission geometry requires samples that are sufficiently transparent for the type of X-rays used. The incident X-ray beam fully penetrates, and is transmitted through, the sample with only moderate attenuation.

The advantages of transmission geometry in powder diffraction are detailed:

- Generally, transmission mode is good for low density samples or weakly absorbing materials; i.e. pharmaceutical substances, proteins, synthetic polymers (foils and fibers) and other organic materials.

- Small amounts of sample are sufficient. We can transfer the sample into a thin capillary or in horizontal sample holders in our setup.

- Fluids; i.e. liquid dispersions can be measured.

- Air-sensitive samples can be sealed in a capillary or between kapton foils.

- Reduction of the preferred orientation effects in powder samples.

- To obtain accurate Rietveld refinements. Using this geometry the data resolution is increased due to much quantity of sample is illuminated by X-rays and as a consequence it enhances statistics.

SAXS Geometry

Advantages of SAXS measurements

This technique allows sensitive measurements of the X-rays that are just barely scattered by the sample (scattering angle < 6°) using a transmission geometry. The length scale of d(Å) is inversely proportional to the scattering angle, therefore, small angles represent larger features in the samples.

This angular range contains information about the shape and size of nanoparticles and porous materials, characteristic distances of partially ordered materials, and pore sizes distributions. SAXS is capable of delivering structural information of macromolecules between 5 and 25 nm, of repeated distances in partially ordered systems of up to 150 nm.

Applications

The most common applications for these measurements are:

- Nanoparticle size distribution

- Particle shape

- Specific surface area

- Pore size distribution

Contact

-

Jessica Padilla Pantoja

Jessica Padilla Pantoja

Research Technician of the X-ray Diffraction Facilities

jessica.padilla(ELIMINAR)@icn2.cat

Tel. +34937372638

Associated Groups/Units