Electron Microscopy Unit - Case Studies

Electron microscopy has become a key characterisation tool since it provides structural, chemical and morphological information of a wide range of nanomaterials and nanostructures. Recent developments in both scanning and transmission electron microscopes have dramatically improved their image and nanoanalysis capabilities, making feasible for instance the day-to-day study of crystallographic periodicity of structures at the atomic level and the study of high-vacuum incompatible specimens by SEM working in environmental mode, among others.

Since the installation of the equipment in 2012, a wide variety of studies have been performed in the Electron Microscopy unit. Here we show some representative examples:

- Case Study 1: IN-SITU GROWTH OF ICE IN THE ESEM

- Case Study 2: DETERMINATION OF THE ELEMENTAL DISTRIBUTION OF CORE-SHELL NANOPARTICLES BY STEM-EELS

- Case Study 3: CASE STUDY 3: CHEMICAL STUDY OF FUNCTIONAL GRAPHENE

- Case Study 4: INTERACTION OF CARBON NANOTUBES WITH CELLS

- Case Study 5: STUDY OF FLAKE SIZES IN 2D MATERIALS BY XHRSEM

- Case Study 6: IN-SITU SAMPLE HEATING FOR DEGRADATION TEMPERATURE DETERMINATION

- Case Study 7: REAL SURFACE IMAGING AT EXTREME LOW VOLTAGES

- Case Study 8: HIGH RESOLUTION IMAGING OF NON-COATED INSULATING SAMPLES

- Case Study 9: ELEMENTAL DISTRIBUTION OF Ni/ZnO CATALYST BY SEM-EDX

- Case Study 10: ELEMENTAL DISTRIBUTION OF Fe3O4/Mn3O4 CORE-SHELL NANOCUBES BY SEM-ED

- Case Study 11: NANOTUBES FILLING IMAGING BY SEM

- Case Study 12: HIGH QUALITY LAMELLA PREPARATION FOR HR(S)TEM ANALYSIS

- Case Study 13: MICROSTRUCTURES FABRICATION THROUGH FOCUS ION BEAM (FIB)

- Case Study 14: SrTiO3 EDX ATOMIC-SCALE MAPS

- Case Study 15: SrTiO3 EELS ATOMIC-SCALE MAPS

- Case Study 16: LOW-DOSE (< 1pA) ATOMIC-SCALE STEM IMAGING OF A ZEOLITE

- Case Study 17: ATOMIC-SCALE IMAGING

- Case Study 18: MONOCHROMATED EELS FOR FINE STRUCTURE ANALYSIS

CASE STUDY 1: IN-SITU GROWTH OF ICE IN THE ESEM

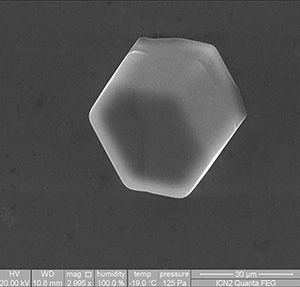

Controlling the freezing of water to form ice crystals on any type of sample allows us to obtain interesting and useful results for different research topics related to industrial applications such as efficiency improvement in artificial snow production, the prevention of ice formation in the food industry, machinery protection, and preservation of biological samples, among others.

We are able to in-situ grow ice in the FEI Quanta 650FEG ESEM by a careful control of temperature and humidity conditions using a Peltier cell.

CASE STUDY 2: DETERMINATION OF THE ELEMENTAL DISTRIBUTION OF CORE-SHELL NANOPARTICLES BY STEM-EELS

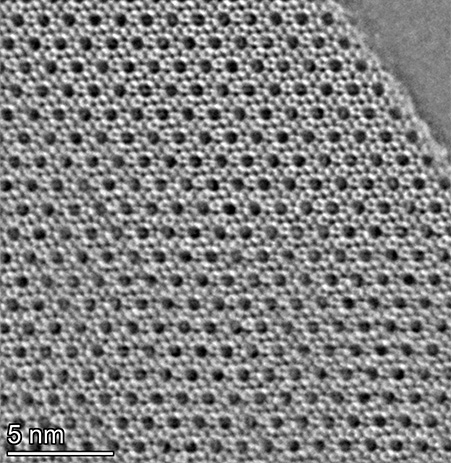

The FEI Tecnai G2 F20 HR(S)TEM, equipped with a Gatan Imaging Filter (GIF) Quantum SE 963, allows for elemental line profiling and mapping of nanoparticles, among others. Using STEM-EELS we are able to determine the location of Fe2O3 and Mn2O3 in core-shell nanoparticles of less than 5 nm in size. The STEM-EELS map has been acquired at 80kV in order to avoid sample damage. Note that the Mn2O3 shell is about 1nm in thickness.

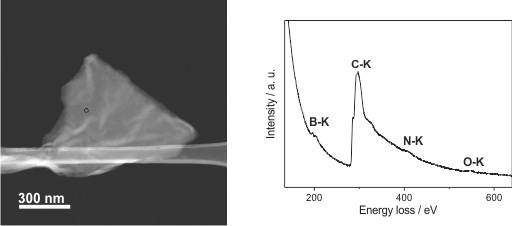

CASE STUDY 3: CHEMICAL STUDY OF FUNCTIONAL GRAPHENE

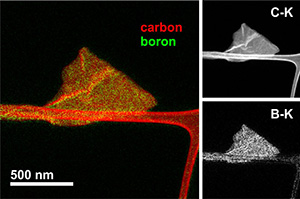

EELS proves useful to detect the chemical composition of functionalized graphene samples. As an example, the EELS spectrum of amine-functionalized dodecahydrocloso-dodecaborate (B12) anions grafted on graphene oxide is shown here, where energy loss peaks with onsets at 188 eV, 284 eV, 401 eV and 532 eV correspond respectively to B, C, N and O contained in the sample.

Besides, mapping the K-ionization edges of B and C by Energy Filtered TEM (EFTEM) we can observe that carbon is found both on the graphene flake and the carbon support film, whereas the boron map only shows bright intensity on the graphene flake, proving the successful functionalization of the flake and the homogeneous distribution of the functional moieties.

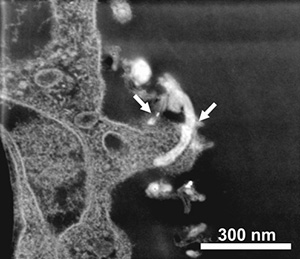

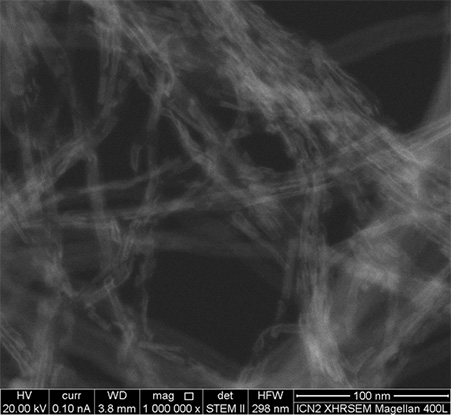

CASE STUDY 4: INTERACTION OF CARBON NANOTUBES WITH CELLS

Investigation of the ability of amino-functionalized multi-walled carbon nanotubes (MWNTs-NH3+) to cross the Blood-Brain Barrier (BBB) has been carried out by low voltage STEM imaging. Solid evidence using electron microscopy for each step of the transcytosis process.

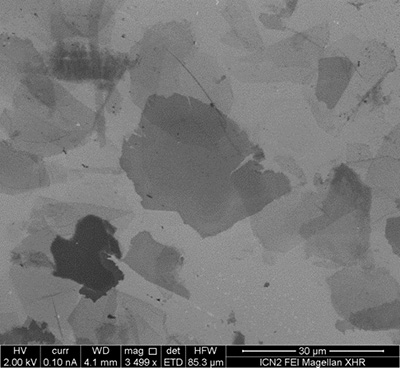

CASE STUDY 5: STUDY OF FLAKE SIZES IN 2D MATERIALS BY XHRSEM

The Magellan XHRSEM can be operated at low voltages with excellent resolution, which provides extreme sensitivity surface images as those required for imaging 2D materials flakes. For instance, graphene can indeed be studied deposited not only on conducting substrates but also on non-conducting surfaces, such as silicon oxide. The electron beam deceleration mode together with the use of a high sensitivity backscattered electrons detector is used to image non-conducting samples.

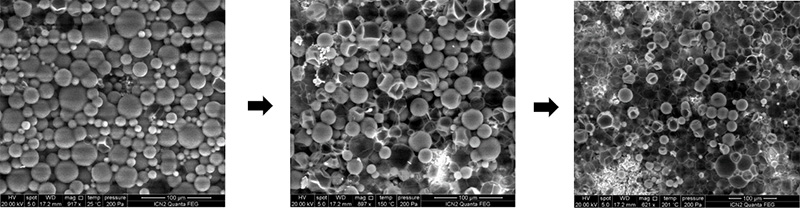

CASE STUDY 6: IN-SITU SAMPLE HEATING FOR DEGRADATION TEMPERATURE DETERMINATION

With the heating stage available in the Quanta 650FEG ESEM we can carefully control the temperature on the samples and analyse how they evolve while acquiring images and recording videos. Degradation temperatures, fusion points, structure changes, and many other characteristics can be determined up to 1000 °C with temperature ramps up to 40 °C/min at nanoscale resolution.

In this case researchers want to determine the degradation temperature of organic capsules in order to find out if they are suitable for their final application, where they will be under high temperature environments. The degradation temperature is determined at ~150 °C (middle image) where, as can be seen, the capsules start to degrade.

CASE STUDY 7: REAL SURFACE IMAGING AT EXTREME LOW VOLTAGES

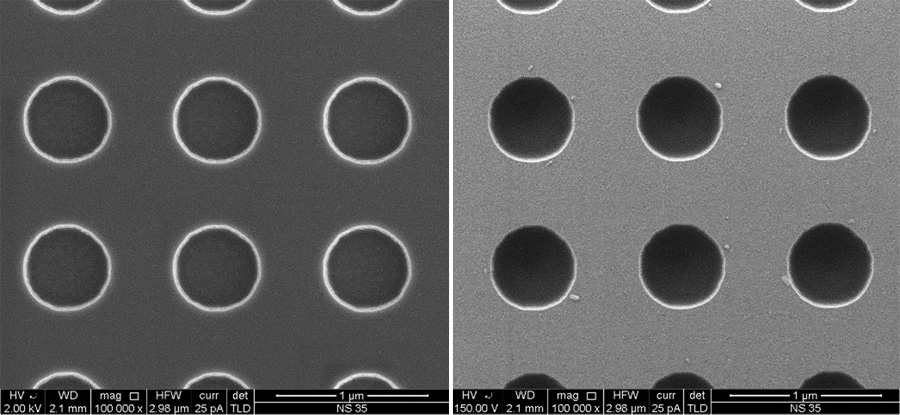

Detailed and real surface images have always been extremely difficult to acquire on the SEM, as the resolution of the microscopes decreases when lowering the voltage and they start to be almost impossible to operate below 500V electron beam energies. With the Magellan 400L XHRSEM images can be acquired down to 50V electron beam energies, so real and detailed surface images can be acquired at nanometric resolution.

A comparison between 2kV (low voltage; left) and 150V (extreme low voltage; right) of a pattern of circular holes on Si wafer is shown below:

As can be seen, the left image shows the circular pattern and the solid and smooth surface of the sample as expected for a silicon wafer at low voltage imaging, but when acquiring an image at 150V real surface details appear. Acquiring images at extreme low voltages allow to see the true surface of the sample, i.e. nano-rugosity and nanoparticles are clearly seen. This is possible thanks to the Beam Deceleration mode of the microscope that allows to work with energies down to 50V keeping the resolution of a 1 to 4 kV electron beam.

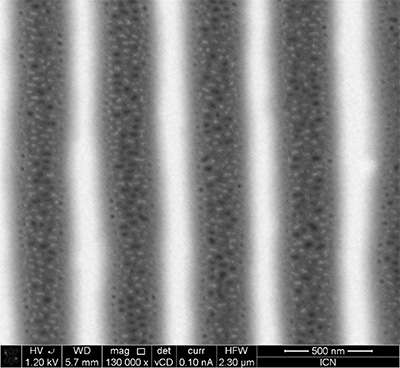

CASE STUDY 8: HIGH RESOLUTION IMAGING OF NON-COATED INSULATING SAMPLES

Combining the low voltage-high contrast (vCD) backscattered electrons detector, equipped on the Magellan 400L XHRSEM, with the Beam Deceleration mode available, we are able to acquire charge free images of non-coated insulating samples at nanometric resolution.

Here we show an Image of a nanoimprinted block copolymer poly(styrene-b-polyethylene oxide). The line pattern of the stamp was replicated with high resolution in the block copolymer film, while the shear forces occurring in the imprint process induced the BCPs microphase segregation resulting in the nanopores observed in the trenches.

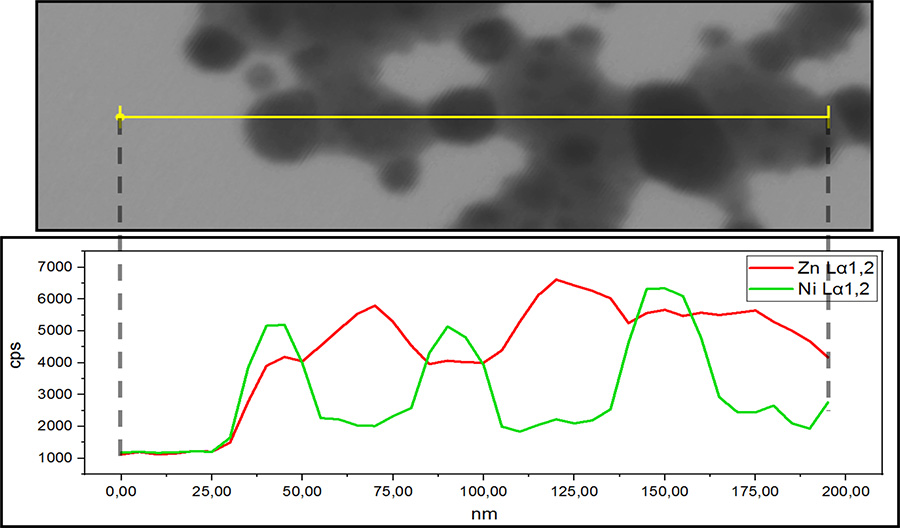

CASE STUDY 9: ELEMENTAL DISTRIBUTION OF Ni/ZnO CATALYST BY SEM-EDX

Combining STEM imaging mode available at the Magellan 400L XHRSEM with the X-Max Ultim Extreme EDX detector, we are able to perform EDX linescans and mappings with unprecedented resolution on a SEM.

Below, an EDX linescan shows the elemental distribution of a Ni/ZnO catalyst sample, where the Ni catalyst is supported over ZnO. With a beam step of only 5nm at 10kV, the sample elemental distribution can be clearly resolved. Acquisition time: 5 minutes. Linescan total length: 195nm.

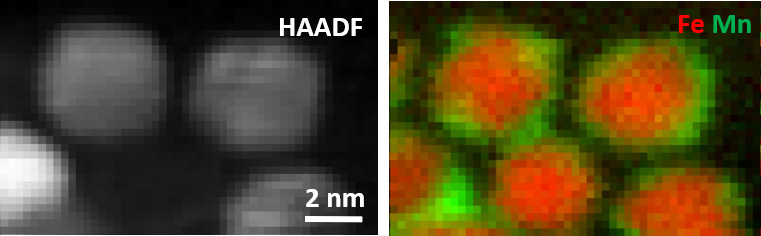

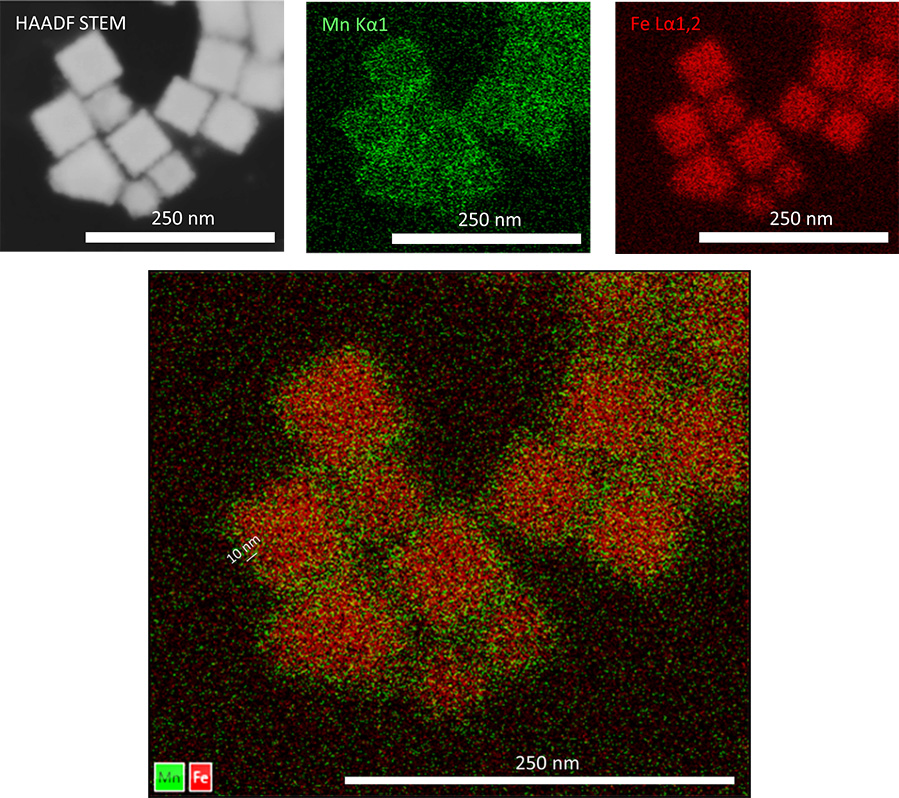

CASE STUDY 10: ELEMENTAL DISTRIBUTION OF Fe3O4/Mn3O4 CORE-SHELL NANOCUBES BY SEM-ED

Combining STEM imaging mode available at the Magellan 400L XHRSEM with the X-Max Ultim Extreme EDX detector, we are able to perform EDX linescans and mappings with unprecedented resolution on a SEM.

Below, an EDX mapping shows the elemental distribution of Fe3O4/Mn3O4 core-shell nanocubes, with a 2nm pixel size, acquired at 10kV, the core-shell structure can be clearly resolved. Acquisition time: 10 minutes.

CASE STUDY 11: NANOTUBES FILLING IMAGING BY SEM

STEM imaging mode available at the Magellan 400L XHRSEM provides the highest resolution (<1nm@20kV) images available in a SEM. The example shows inorganic nanotubes (PbI2) filling inside carbon nanotubes.

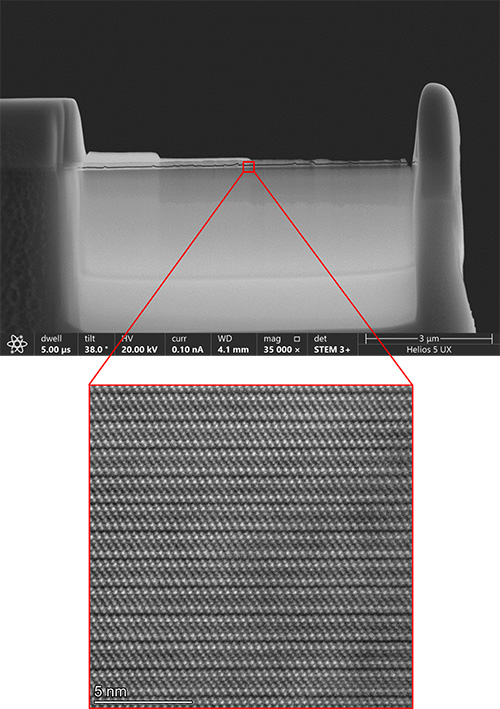

CASE STUDY 12: HIGH QUALITY LAMELLA PREPARATION FOR HR(S)TEM ANALYSIS

The Thermo Scientific Helios 5 UX DualBeam provides the ability to produce exceptional sample lamella for high resolution transmission electron microscope (HRTEM) analysis, as can be seen in the image. With its Thermo Scientific Phoenix Focused Ion Beam (FIB) Column, we are able to produce high quality sample lamella with an ion beam milling energy and ion beam current down to 500V and 1pA respectively. This capability lets us prepare sample lamella with zero amorphization on the crystalline structure even in soft materials.

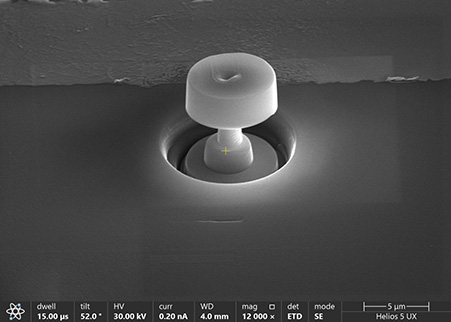

CASE STUDY 13: MICROSTRUCTURES FABRICATION THROUGH FOCUS ION BEAM (FIB)

A FIB system has four basic functions: milling, deposition, implantation, and imaging. Milling is a process that allows digging into the sample surface as a result of the use of Ga ions in the beam. It also has a deposition system simply by adding a gas delivery device that allows the application of certain materials, usually metals, to the surface of the material where the beam strikes. When combined with milling, FIB deposition can create almost any microstructure. The image below shows a microstructure fabricated with our Thermo Scientific Helios 5 UX DualBeam.

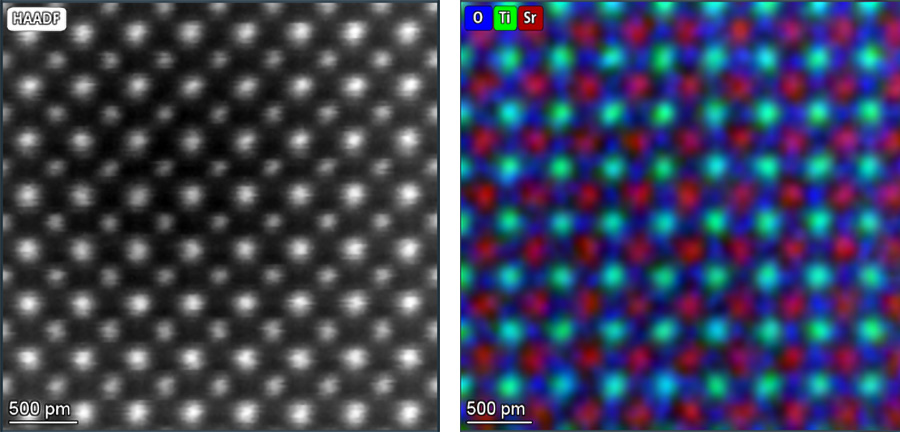

CASE STUDY 14: SrTiO3 EDX ATOMIC-SCALE MAPS

The Thermo Fisher Scientific Spectra 300 (S)TEM is a double-corrected transmission electron microscope that can be operated in either TEM or STEM mode and is equipped with an ultra-high energy resolution field emission gun (X-FEG) and a monochromator (UltiMono). With its Super-X windowless EDX (4 quadrant SDD EDX detection; solid angle > 0.7 srad) atomic-scale maps can be acquired as the one shown below from a SrTiO3 sample. This EDX atomic-scale map was acquired in 3.5 minutes.

CASE STUDY 15: SrTiO3 EELS ATOMIC-SCALE MAPS

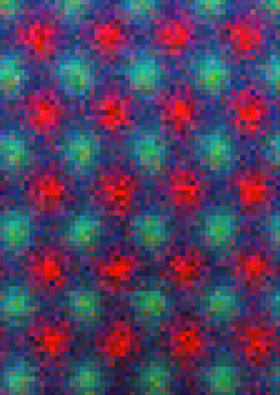

The Thermo Fisher Scientific Spectra 300 (S)TEM is a double-corrected transmission electron microscope that can be operated in either TEM or STEM mode and is equipped with an ultra-high energy resolution field emission gun (X-FEG) and a monochromator (UltiMono). It is also equipped with a Gatan GIF Continuum K3 energy filter for EELS and EFTEM applications (>3000 spectra per second at >95% duty cycle), with low-noise, a high dynamic range CMOS 1069.EXUP (30-300 kV) detector and the K3 electron counting direct detector (80-300 kV) for the ultimate EELS and EFTEM data quality. Below, a SrTiO3 sample atomic-scale EELS map is shown (Sr in red, Ti in green and O in blue). This EELS atomic-scale map was acquired in 35 seconds.

CASE STUDY 16: LOW-DOSE (< 1pA) ATOMIC-SCALE STEM IMAGING OF A ZEOLITE

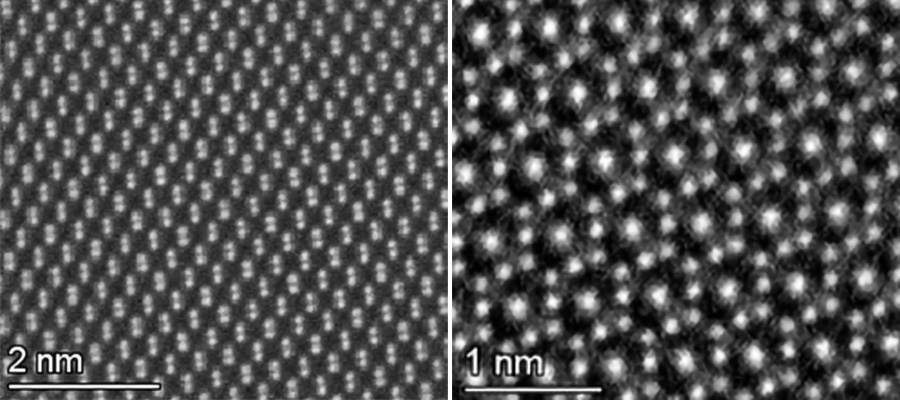

The double-corrected Thermo Fisher Scientific Spectra 300 (S)TEM is equipped with the Panther detector: an on-axis solid state segmented detector composed by an 8 segments circular detector (BF) and an 8 segments circular detector (ADF/ABF/DPC) (16 segments in total).

Besides other applications, we can exploit this detector for extreme low-dose imaging (<1pA probe current). In this example, an iDPC image is shown obtained from a Zeolite crystal, a material that easily becomes amorphous under the electron beam.

Note that this imaging mode even allow us to detect the presence of some C atoms that are encapsulated within the channel positions of the Zeolite sample.

CASE STUDY 17: ATOMIC-SCALE IMAGING

The double-corrected Thermo Fisher Scientific Spectra 300 (S)TEM allows us to acquire atomic resolution images on many different materials, as shown below for semiconductors (left) or ceramics (right).

CASE STUDY 18: MONOCHROMATED EELS FOR FINE STRUCTURE ANALYSIS

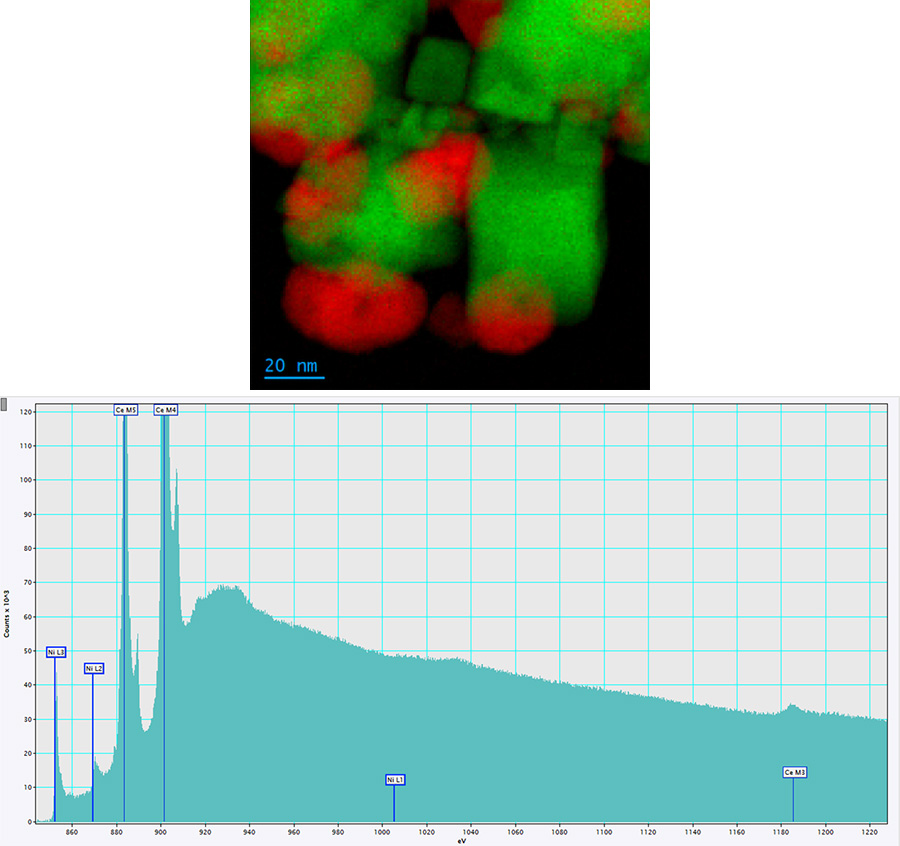

The double corrected Thermo Fisher Scientific Spectra 300 (S)TEM is equipped with a Thermo Scientific X-FEG UltiMono (monochromator).

In the example below a Ni (red) and Ce (green) compositional map is shown. As observed in the EELS spectrum of the lower panel, the Ce M and Ni L are located very close to each other which makes it very challenging to properly deconvolve them without monochromating the beam.